-

Solution Technologies

Automation

Automation

Automatic Frame Joining | Labor Savings | Frame Building Integration -

Select By Application

-

Automation

-

Double Mitre Saw Cutting

-

Joining

-

Assembly and Finishing

-

Saw Blade Cutting

-

Hanging and Display

-

Cutting

-

Automated Glass Cutting

-

-

Products

- Video Gallery

- Brands

- Catalogs

- Contact

Fletcher Business Group US - Cutting Force - Cutting force works in conjunction with the cutting wheel diameter and angle

- Cutting Wheel Diameter & Angle - When selecting the appropriate cutting wheel, one needs to determine glass thickness and if straight or shape (pattern) is needed

- Speed of Cutting Wheel - Typically operating parameters are set to yield a certain score quality, ease of break-out, and edge quality

- Cleanliness of Glass

Created from an exclusively formulated micrograin, tungsten carbide composition for extraordinary strength and resilience

- Lubrication treatment is applied to each Fletcher cutting wheel & axle pro-longing life of cutting edge by reducing friction

- Our precision ground, tungsten carbide axles are available in outside diameters of .049” (1.25mm) to .116” (2.95mm), and offered in 9 different lengths

Carbide Glass Scoring Wheels Automated Glass Cutting

CNC Produced HIgh Speed Scoring Wheels

Colorized Cap Package Identifying Wheel Angle

Individual Blister Packaged Wheel, Axle and Insert Assemble

High Speed Carbide Scoring Wheels (CHS)

Fletcher’s “CHS” (CNC Ground, High Speed Score) carbide wheels are produced from a specially formulated micro-grain tungsten carbide material developed exclusively for Fletcher-Terry.

This fine particle carbide composition gives each cutting wheel extraordinary performance strength and resilience. Our formula ensures the cutting properties of our wheels remain consistent, which means superior edge quality and easy clean break out for your end glass product.

Fletcher’s CHS Carbide wheel is produced using a CNC proprietary method resulting in top scoring performing for high-speed glass scoring applications commonly found in float plants.

Depending on glass thickness and type, Fletcher’s CHS Wheels are available from 119° to 155° angle. Scoring wheels can be packaged individually in tubes of 20 wheels or pre-assembled with wheel, axles and insert packaged in blister type packaging.

What Makes the CHS unique and different from other glass scoring wheels

1. CNC manufacturing batch start-up requires a percentage of wheels be

approved prior to full batch production

2. In-process batch control continues through-out the CNC grinding process for

maintaining the strict QC standards

3. For final QC inspection, Fletcher utilizes an in-house designed and fabricated

high speed testing system for qualifying wheel scoring quality and consistency

High speed testing at 40 inches/second

Glass Scoring Application Form

Shop for cARBIDE GLASS SCORING WHEELS

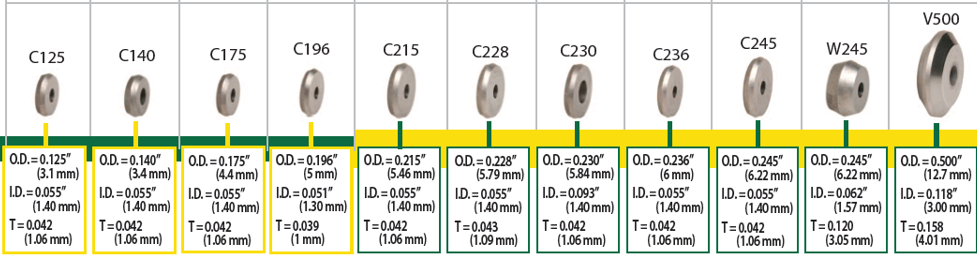

Selecting a Carbide Wheel

When selecting the proper wheel, Fletcher recommends a four step selection process.

Step One: O.D. Selection – Determine the outside diameter of the wheel based on thickness of the glass. Smaller O.D.’s provide for finer adjustment, larger I.D.’s provide extend life.

Step Two: I.D. Selection – Determine the inside diameter

Step Three: Angle Selection – Determine type of cut either Straight or Shape cutting. Refer to charts below for additional information.

Step Four: Wheel Grind – RG (Regular Grind) most versatile grind used for straight and shape cutting; CR (Course Grind) used for tube cutting and for irregular surface cutting; PL (Polished) use for very thin and specialty glass cutting

Related Products

Market exclusive packaging designed to package Fletcher’s line of carbide cutting wheels, inserts, clip units and axles

View ProductBlister & Colorized Tube Packaging

Our precision ground, tungsten carbide axles are available in outside diameters of .049” (1.25mm) to .116” (2.95mm), and offered in 9 different length…

View ProductCarbide Axles

Angles from 88 to 165 degrees Regular, Course and Polished Wheel Grinds

View ProductCarbide Glass Scoring Wheels

Proprietary “positive lock” capability guarantees the insert will not jar loose even under extreme shock or impact

View ProductM1 & ATF Inserts

Fletcher’s pre-assembled metal carbide wheel unit includes one carbide cutting wheel and carbide or steel axle seated in a heavy duty metal clip.

View ProductMetal Carbide Wheel Units

Adaptable to popular OEM Glass Cutting Machinery - Bottero, Hegla,Grenzebach, Billco, Bystronic, GED, Bando and Ianua

View ProductPillar Post & Wheel Units

Fletcher’s pre-assembled plastic wheel unit includes one carbide cutting wheel and carbide axle assembled into a plastic insert holder.

View ProductPlastic Carbide Wheel Units

Contact Us

If you are an existing FBG Equipment Customer and are looking for Spare Parts, Cutting Blades and Wheels, or equipment accessories, please visit the company’s online store at shop.fletcher-terry.com.

CORPORATE & MANUFACTURING HEADQUARTERS

91 CLARK DRIVE

|

EAST BERLIN, CT 06023 USA/CANADA

|

860.828.3400

|

CUSTOMER SERVICE

800.843.3826

INTERNATIONAL MANUFACTURING HEADQUARTERS

Via Marie and Pierre Curie, 3

|

47122 Forli, Italy

|

Customer Service

+39 (0)543 78 33 01

FRAMEWARE MANUFACTURING AND WAREHOUSING

8 Audrey Place

|

Fairfield, NJ 07004

|

Customer Service

973.808.2022

ATLAS SAW AND TOOL MANUFACTURING, WAREHOUSING AND GRINDING SERVICES

7801 Industrial Court, Suite B

|

Spring Grove, IL 60081

|

Customer Service

888.484.1488

SIMMS MACHINERY SALES AND SERVICE

170-B S. Orchard St

|

Yoe, PA 17313

|

Customer Service

800.527.4667

© Copyright 2026 Fletcher-Terry Company, LLC.

All rights reserved. Site designed and hosted by WORX.